radellaf

-

Posts

218 -

Joined

-

Last visited

Content Type

Profiles

Articles

Media Demo

Forums

Gallery

Events

Store

Blogs

Downloads

Posts posted by radellaf

-

-

Maybe they use so much FO that there is no wick that won't mushroom. Frankly, with the amount of stink that seems to be the recent trend, people would be better just burning whatever they like the look of, and sticking an open jar of fragrance somewhere inconspicuous. Probably healthier, too...

-

For soot I recommend steaming the inside of the jar (teakettle or the like) and a wipe with a paper towel.

-

That's definitely one to search for on here, lot of info.

Briefly, anywhere from 1-30%. 1tbs pp is roughly 1.6% but depends on the physical form of the stearic. Lowers melt point, increases hardness and opacity.

I sometimes use 2% in mottled pillars or 10% in tapers. Really touchy on the wicking especially at low %. 2 to 3 is one wick size diff for me.

I guess I mostly use it for the look, as at 2% it doesn't harden my wax enough or really increase FO holding. A bit of each maybe... more makes the wax too opaque for my taste for pillars, tho I'm OK with that for tapers.

-

I usually clean out containers by heating an inch or two of water in a pot and putting the containers in for a few min. But then, I usually re-use the residue by pouring it all into a mishmash container candle (avoiding excess carbon chunks or picking them out with a big tweezer)

Molds usually just running hot tap over the outside and then wiping the inside.

Oven method does sound less labor intensive.

-

I find palm in general easier and more consistent than soy...

My guess with the bottoms there is that it has to do with the thickness of the glass. I bet the preheat didn't fully warm the bottom. Could try sitting the jars in hot water instead of or in addition to hot air.

CSN-16 sounds right for the 10oz cube, but maybe not for that scent? Try 22 I guess...

-

The expense should be reasonable if you can get started with two waxes, a mold or two, bag of stearic and maybe a dozen wick sample packs. Even if you don't like experimenting (it's my favorite part), then the pain should be over shortly. If your supplies are reasonably chosen and you're not a perfectionist, then I have great confidence that within 10 or 20 tries of the same type and size, you'll have a winner. Be systematic, and not afraid to remelt one to try a different wick (or yank and drill...) or more stearic.

I might say I have few I'm thrilled with, but then I make all sorts of sizes and types, plus scents, which complicates the matter greatly, but the variety keeps it interesting. Other benefit is that I _always_ have candles to burn and, unlike storebought ones where I used to think of every burn as costing something, now every burn is justified as a further experiment

Like was said, the commercial candles out there are highly variable in how well they burn, and most of my "failures" are no worse than some.

-

-

Tired of taking people's word about whether or not soy makes soot, and whether it's white, I'm doing an experiment.

I just got some ridiculously large wick (CandleScience CSN-26) and am trying it with EcoSoya CBA in a 6 oz hex jar that, properly wicked, would use a CSN-9 (for soy) or CSN-7 (for palm). Touch of yellow dye, no scent.

So far...

I'm right. Soy can soot, and the soot is black. Score one for physics there. The only white soot I could find reference to on the web, other than in soy promotion, was from the tetraethyl lead in aviation fuel. Or, the remains from a magnesium fire. That makes sense. Metal oxides can be white. Carbon can't.

Furthermore, if soy didn't produce fine black carbon particles, the flame wouldn't have that nice yellow glow. The glow is from those carbon particles getting very hot. If the mix is right, the carbon completely oxidizes into CO2. A sooting flame is just throwing off cooler particles that never have a chance to burn up.

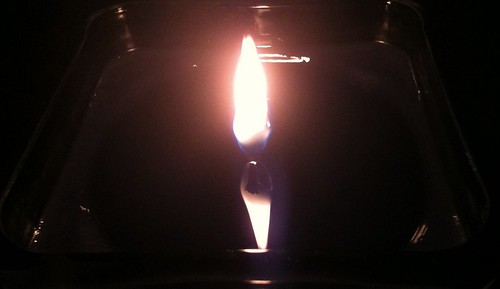

However, I have to admit that this candle isn't sooting much, and sometimes burns like in the picture. Nice perfect curling-over wick and a decent flame height. Normally my soy candle flames are kind of anemic looking, if sized to make normal depth melt pools and not roast the glass container at the end.

This wick is a _rope_. It's a bit bigger than 42 ply. I was expecting a cloud of black smoke. I'll burn this off and on down to the bottom (in a safe enclosure), and see if it comes out with glass as black as a lot of paraffin containers end up being.

-

11.5oz IGI 1274

0.5% IGI Microsere 5715 (170 MP, 28dmm)

3.7% (12ml) Cucumber Melon

2 drops olive

3" pillar

LX-16 (partial mottle, no bleed)

CandleScience had their warehouse sale last weekend and I picked up some things they don't normally stock, including this dye (it really is olive, better pics later) and 15 pounds of micro wax (all wax was 25c/lb).

No idea how it'll burn. Wick is right for 0-2% stearic. Doubt this little of this micro will harden it enough to discourage bulge. They had higher MP micro there but I only asked about mottle control and not hardening so I missed out on it. Still, the mottle pattern is great, there is absolutely no surface oil. I'll have to see how it holds up to different fragrances, but at the moment looks like I found a winner, and at 0.5% I have enough to last a very long time.

Outside of that one-time sale, the only supply of hard (190) micro I can find online is at GenWax, at $5/lb+$10s/h. The only other is Candlewic's 180 at ~$3/lb.

The 0.5% Clear Crystals (FT wax from CandleChem) does a similar amount of mottle with 3% FO. The wax looks more clear or "jewel tone"-like with that, whereas the micro leaves it about like it would be with no additive. Stearic, even at 2%, makes the wax slightly more opaque and doesn't help much with bleed. I kind of like the clear look, but it is odd. What I have here looks just like the expensive ones in the stores. Whole Foods has Pacifica for I think $20 for a 3x6. Target and K-Mart have similar for a little less. The pros still have an edge on the fragrances, though. Illume's Sahara Sage and Pacifica's Sandalwood, for instance, are heavenly.

-

I do love frosted tumblers, one of my favorites for my own use.

I thought this boutique could really use something new to perk up their selection, which right now is undyed soy only, in a shop full of odd colorful stuff from handcrafted blown glass to unique but mass produced toys and games. Bright colors of palm would do the trick but need clear for that. Honestly tho I'd be surprised if she'd order more than a half dozen at a time.

-

I've had some success dual or tri wicking in the same wick pin hole. You have to determine the curl direction and make sure they curl away from each other. Main problems with this are that the "spacing" between wick sizes is large. 2xLX-8 to 2xLX-10 can be a big gap. Worse of course with three. Other prob is that sometimes they don't curl apart on thieir own and need a prodding.

If starting out, don't bother, but fun for experimenting later.

But, if you want a larger flame with lower smoke it is the way to go.

-

I'm short of customers, so may be worth a try, esp if they'll pre order at least enough to cover a test order of jars. I don't mind doing the testing, it's kinda fun, and I have enough palm wax experience I should nail it pretty quick.

That said, yeah, you may be right. I just found one other who wants "something country", so jj are worth a try. Also a new size for me but a good one to know.

-

I'm short of customers, so may be worth a try, esp if they'll pre order at least enough to cover a test order of jars. I don't mind doing the testing, it's kinda fun, and I have enough palm wax experience I should nail it pretty quick.

That said, yeah, you may be right. I just found one other who wants "something country", so jj are worth a try. Also a new size for me but a good one to know.

-

Thanks. They have the 8oz tumbler & jar available in small quantity, a dozen for $37 w/shipping. Look very nice to me.

-

Depending how the "bottom" is finished I sometimes think it looks better for the top, and then also you avoid the problem of trying to get a perfectly level bottom, which can be tricky on taller pillars. OTOH, if you do nothing like some blowtorch work the yeah, the bottoms can look bad.

-

Anyone know a supplier for jars and lids that don't have a screw top?

90% of what I see uses screw tops, but I just had a potential boutique store manager tell me that when the lid is off that "it looks like someone just made a candle in a baby food jar.". Hmph.

I see plenty of straight-top jars, but nothing sold to cover them. Commercially there are really nice lids using a rubber gasket to loosely hold a metal lid on, but this customer said even a lid with no attachment, just a cover that sits there, might be sufficient.

...should have brought rustic pillars samples instead.

-

Was mentioned that EVA is part of hot glue, so here's an experiment in using 1% by weight of a multi-temp hot glue stick as an additive in IGI1274, 3%FO. Completely opaque and very shiny. Looks a lot like the polyethylene additive. Had to get the wax up to about 250F for the bit of hot glue to dissolve, but it did.

-

-

Just got in my CandleChem order and here's what their additives look like.

Translucent Crystals:

Clear Crystals:

Are one or both of those "FT Wax" or "Paraflint"? Either dissolved fine when I got a few ounces of wax in my pour pot, on direct heat, up to about 250F. Only the translucent came with a big warning to MELT SEPARATELY.

And here are two candles, top made with translucent at 0.5% and bottom with clear at 0.7% by weight (both 1 tsp pp). Sorry, couldn't resist burning the top one. But it wasn't very translucent, and had only a few flecks of mottling. Both 3% CS Dragon's Blood FO.

I kinda like the bottom one with the clear crystals, though not sure what caused the messy bottom-of-the-mold end. It was poured at at least 185F.

I'll have to try the translucent crystals at 0.25% (half) and see what I get. We're talking really small amounts here, in 5oz candles. Like 2-3 grams.

-

Well, nice, thanks for clearing that up

. I'd only heard eutectic as regards SnPb solder. Also explains why I had a no stearic 3 wick sag, but not blow out, and a 3% melt right over. Well, could be other causes ... OTOH, 10% does make my tapers not drip. Not sure why, somehow slows down how much melts vs is consumed, and don't see how that works if MP is lower. Curious.

. I'd only heard eutectic as regards SnPb solder. Also explains why I had a no stearic 3 wick sag, but not blow out, and a 3% melt right over. Well, could be other causes ... OTOH, 10% does make my tapers not drip. Not sure why, somehow slows down how much melts vs is consumed, and don't see how that works if MP is lower. Curious. Hadn't though hardness and MP could be separate. Guess it makes Paraffin more like palm wax.

-

link or pics? I'd like to see them...

-

I thought it would raise the MP of paraffin with a MP lower than it (150-ish):

From: http://www.howtomakecandles.info/cm_article.asp?ID=ADDIT0003How and when to use Stearic acid?

In our domain, candlemaking, Stearin (that's how I'll call it from now on) is available in powder or granulated form, has a pure white color and feels a little fat when you touch it. Its melting point is 158°F.

It is mainly used:

to raise the melting point of the paraffin it gets mixed with (logically, one part paraffin with a melting point of 130°F mixed with one equal part paraffin with a melting point of 150°F results in a mixture whose melting point averages 140°F). Adding a substance with a high melting point - like stearin - to paraffin has a tendency to raise the average melting point of the mixture,

on the contrary, to lower the melting point of a high melting point paraffin,

to give the colors a pastel shade,

to "harden" the candle. Stearin can act as a hardener,

to make the candle burn longer (due to the fact that the melting point is higher).

also http://www.happynews.com/living/create/using-stearic-acid.htm

-

I actually notice the flame is HUGE on my soy candles, much larger than my paraffin or parasoy blends. That's a huge part of the problem with soy candles for me, everything else I've got down pat pretty much.

How strange, well, goes to show how differently things work for each of us. However, main cause is probably that I have never tried to make container candles that deep. Partly, because I haven't seen any that burned all that well without a lot of trimming, soot wiping, and wick re-positioning... capper helps with the flickering and reduces soot, but still. And, I've never seen one that large with that little "hang". Usually there is hang most of the way around. Long as it's throwing scent well I'd be happy, but here's hoping your efforts get you perfection

FWIW, here's a "big" soy flame for me:

CBA, 12oz cube, 6% FO, twin CSN-12

Same jar with LX-20 and 4630, massive 2"+ sooting flame unless trimmed very short between lights. LX-16 or 18=tunnel.

-

Genwax has a micro 195, and there are the clear crystals here: http://www.candlechem.com/additives.htm

I just ordered the crystals but haven't tried them. Stearic will certainly harden the wax but it will make it opaque.

Pillar dust covers....

in General Candle Making Discussions

Posted

There are these for containers:

http://www.generalwax.com/glass-container-jars--lids---gift-boxes/pvc-metal-lids-for-glass-candles/cate_105/p___P0906287.html

Not familiar with anything for pillars tho...