scottopus

-

Posts

84 -

Joined

-

Last visited

Content Type

Profiles

Articles

Media Demo

Forums

Gallery

Events

Store

Blogs

Downloads

Posts posted by scottopus

-

-

I measure my EVO dyes in grams as shown above-

16 grams of red, 8 grams of green, and 4 grams of yellowMy cheap $24 plastic scale that I got at bed, bath, and beyond with a coupon (20% off from the Sunday paper) was on its last leg.

I bought a scale that HenryK told me about. The KD-7000 Professional Digital Scale from save on scales.

I think for my droppers I will order some of the amber rounds with droppers.

I think for my droppers I will order some of the amber rounds with droppers.Using a glass dropper should work fine. I wanted something inexpensive that I could just throw away after it was empty.

-

Did you allow the "in storage" candle come up to room temperature before burning it? If your wax/container was cold and/or you burn it a cold environment, it won't get as large as a melt pool of a candle that is completely up to room temperature. If on the second burn the candle wax and container warmed up to room temperature, the melt pool would be larger which in turn would melt the tunnel wall drowning out the wick. Just a theory that might explain what happened. I would test it out by getting another candle from the same storage area, letting in warm up entirely, then do you normal test burn. HTH

-

Where do you get these bottles from?

Thank you HenryK for answering correctly. I got the 1 oz (0001-12) size for SKS. I do have a couple left over and I guess I could sell you some if you want to try them out.

What do you mean you mean you premix the colors? You mean you are mixing several of their colors to customize your own, right?Correct. This is how I do a custom color:

Get a couple of toothpicks and mark the toothpick in half with a pencil.

Shake up the colors I'm going to use.

Measure out a small amount of melted wax (100-150g) in a clear glass measuring cup.

Dip the toothpick into the dye to the mark.

Mix the melted wax with the dyed toothpick.

Pour a little bit of the wax out onto a piece of marble covered with wax paper.

It'll harden rather quickly giving you the finished color.

Keep adding colors using a new clean toothpick each time.

Be sure to record how many parts (1/2 toothpick) you use to get your custom color.

Now that you have how many "parts" of each color you need, I make the premix.

Here's a made up example (4 parts red, 2 parts green, 1 part yellow)

This means I have a total of 7 parts (4+2+1)

Since I know that a 1 oz bottle will hold up to 28, I divide 28/7 to get 4.

I multiply each color by 4 to get 16 grams of red, 8 grams of green, and 4 grams of yellow.

To keep it simple, use a number equal to 28 or less that will divide evenly into your total number of part such as 24 if you have 6 total parts or 25 if you have 5 total parts.

I label each bottle with the premix name and date made.

In my candle formula, I call out the number of premix drop per batch.

Hope that helps.

-

Another place that sells EVO dyes is Just by Nature, but they are much more expensive than Candlewic.

I premix my EVO color and put them into dropper bottles.

-

when you say to add 20% of CB 135... I figure that comes to around 3 oz... so out of one pound.. 13 oz of CB advanced to 3 ounces of 135??? Have I got that right, or am I totally screwed up with this!!

If you want 16 oz of the wax blend of 80% CBA and 20% CB 135, then

16 * .20 (20%) = 3.2 oz of CB 135

16 * .80 (80%) = 12.8 oz of CBA

So you are correct

-

I would say that a properly wick container candle after a three hour burn would have a complete or almost complete edge to edge melt pool with a depth of at least 1/4" but not deeper than 1/2". It seem to me that soy burns down first then out. If the candle still has some hang up after the thrid burn, I do another test with a wick one size larger. Another key point is how hot the container is to the touch, flame height, and how quickly you get a edge to edge melt pool. I would choose the smallest wick the meets the criteria for melt pool after a 3 hour burn.

-

Another key to shipping in the summer is to send it out at the beginning of the week so that your package isn't sitting all weekend in a hot truck or warehouse.

I've never frozen or had one of my candles frozen, but I remember threads about strange things happening to soy candles when they freeze. Here's a couple that I've found-

http://www.candletech.com/forums/showthread.php?t=3957

Old board-

-

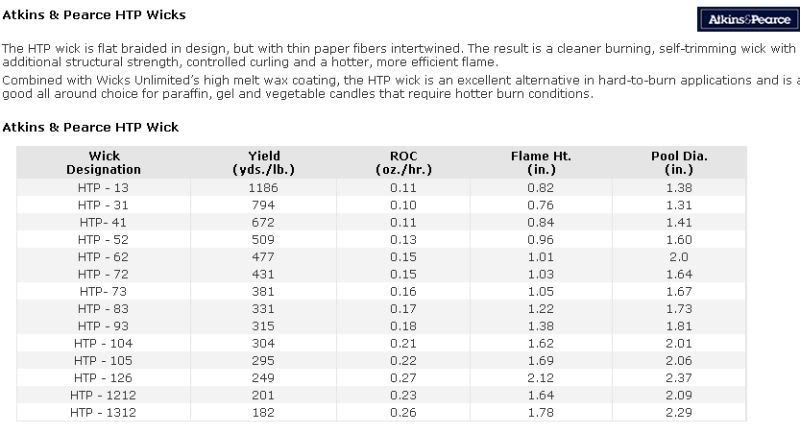

Here's the HTP wick chart from Wicks Unlimited.

-

I would suggest a container that is between 2" to 3" wide and less than 3" tall. Containers with these dimensions are easier to wick.

I started making container candles in 4 oz. quilted jelly jars since they fell within these measurements, were inexpensive (Wal-Mart), and a lot of people have experience with them.

-

Don't know if you know this or not, KY runs a message board-

http://p100.ezboard.com/bkycandlewaxsupplyincmessageboard

You can never have enough information about making candles!

-

I measure my melt pool after the 3 hours. Three hours is the amount of time that are on the burning instructions.

-

I look through a clear ruler that is aligned to the top of melted wax to the point where it still hard.

-

Your not mixing water and oil together, your mixing an oil (wax) with another oil (FO) together. I stir them together when I first add the FO and again before I pour (I pour hot).

-

If I was goiny to try to use buckets, I would try only ones that are made from Vinyl (Polyvinyl Chloride or PVC) or Polypropylene (PP). These plastics will resist the corrosive effect of the FO's better. I've only used the standard metal pouring pots and glass measuring cups.

-

In regards to adding your FO at low temps, I've found/tested that adding at a higher temp produce better results. Here's some reading from the old board-

http://www.candletech.com/cgi-local/yabb/YaBB.cgi?board=veggiewax;action=display;num=1110236703

http://www.candletech.com/cgi-local/yabb/YaBB.cgi?board=veggiewax;action=display;num=1103249348

-

For tarts, I'm using a blend of KY Puresoy and KY all natural Pillar/Votive and loading it to 10% FO.

-

You must have a good nose! I couldn't distinguish between "really strong to lighter throw" as it cools down.

That strength...is what my candle will smell like when lit (because the degrees in my pool is 105)I would say no based on a couple of things. I'm a firm beleiver that soy interacts with FO on a molecular level. This means that your candle is going to change from when it's first mixed and reaches 105 F and when it's "cured" for 5 days and reaches 105F. Another fact is that you might have some straight FO near by (on your hand, a paper towel, on the scale, or table top).

-

When you ask for help on wick sizes, you need to give some information to help us make suggestions. That information is what brand of wax, additives such as beeswax or paraffin, type/amount of FO (fragrance oil), and diameter of container opening.

You know that EZsoy is an all soy wax and IGI 6006 "Vintage Blend" is a soy/pariffin blend.

I can say that if you used a larger wick for a FO in soy you most likely but not always will need a larger one in a blend.

-

When heating the wax with Fo... its pretty strong...then it starts smelling less and less. If it's still strong at 105... it will throw good for me.

Are you saying that you re-heat the wax after it set up or are you talking about when your making candles?

-

Somewhere I saw some low melt soy...115, 119 degrees or somewhere in that vicinity, but for the life of me I can't find it again.

Soy waxes have a range of melt points (111-125 F) depending on the manufacturer. You can get the melt point of the wax by looking at the wax specifications. Matching melt points is not necessary when blending waxes. The new "blend" will have a new melt point that is a product of the waxes used to make it.

-

Good reading from the old board-

There is a lot of information on the old boards. Here's a link to help with your search-

http://www.candletech.com/cgi-local/yabb/YaBB.cgi?board=;action=search

-

Even though most of my tarts (1 oz size) last well over 24 hours, I have one or two that last a little over 12 hours. I just say that they last 12 hours to keep it consistant.

think with tarts you can go 7%-9%Since it's a tart (in other words- no flame), you can load your wax to the upper limits of its specifications.

-

Another STUPID questions

No such thing as a stupid question, other people might also have this question.

I would say that if it's a container that made by a manufacturer (such as Anchor Hocking) that you buy for different distributors, I wouldn't re-test. If it's different companies making a container (such as a 16 oz Apothecary), I would definitely test everyone since there are a lot of differences is glass composition, thickness, and molds measurements.

-

Old board thread about Burning Instructions

Insurance is now available

in Business Side of Things

Posted

Just saw this thread today and was wondering if anyone has any updates or opinions about this insurance.

I've just moved to a new state and feel like I'm back to square one in getting business insurance. This plan sounds great!

Thanks!