ssolis

-

Posts

68 -

Joined

-

Last visited

Content Type

Profiles

Articles

Media Demo

Forums

Gallery

Events

Store

Blogs

Downloads

Posts posted by ssolis

-

-

Oh, and the black does come out a bit in the bubbles, sort of grey bubbles, but it does not stain the hands or sink in any way.

-

I've used a bit of black oxide to get a very desirable black color for Black Licorice this year. I don't think black is going to be your challenge, though... I think white will be. To get a good solid white you have to either use very light oils in a lard base recipe or use titanium dioxide.

Could you make the label zebra-ish instead of the soap itself?

-

Hey, Crafted!

I just want to say that I've been following your soap journey because I decided to learn the technique recently as well (I'm only familiar with candles). You've asked some really great questions and I'm finding the answers useful in my own practice sessions!

Take care!

Sandi

-

are you gellin'? hehe..I ALWAYS wanted to say that..

anywho! your soap looks AWESOME!! great job!

HA! I tried to explain to my hubby the science of soap making with options of gelling... and he said he was lost, that all he could think about was the commercial!

-

Update!

I now understand the diff between gelling and not gelling!

Thank you for all the help and advice!

Sandi

-

Lum,

Thanks for all of this information! I'll take it to heart and deeply consider my other options!

Sandi

-

Alright. I have one batch finished using the advice given. I'm not going to let this one gel (if I can help it)! I spent some QT with the the Palm Oil so we'll see if that was the major culprit regarding the streaks! I didn't put the FO in the oil yet, but if it still streaks, I will take that advice, Top!

Kitn, thank you! You guys are awesome!

-

Thanks, ToMH! I am relieved to know that I am on the right track at least. And nope, I didn't melt and mix the palm oil before measuring or adding to other hard oils! Hmmm, I'll try that to see if I can get rid of the streaks. Do I need to melt and mix the PKO in the same manner?

-sandi

-

Lorrie, it has to do with the environment.

Wikipedia describes:

"Palm oil production has been documented as a cause of substantial and often irreversible damage to the natural environment. Its impacts include: deforestation, habitat loss of critically endangered species, and a significant increase in greenhouse gas emissions. The pollution is exacerbated because many rainforests in Indonesia and Malaysia lie atop peat bogs that store great quantities of carbon that are released when the forests are cut down and the bogs drained to make way for the palm oil plantations. Environmental groups such as Greenpeace claim that the deforestation caused by making way for oil palm plantations is far more damaging for the climate than the benefits gained by switching to biofuel."

However, there are companies, such as Brambleberry that sell sustainable palm oil.

Sandi

-

Can you post your full recipe?

And I wondeer if it is the steric in the palm that I am seeing.

Sure! Here is the first:

12.8oz Olive Oil

8oz CO

4.8oz Palm Oil

9.728oz H20

3.687oz Lye

My second recipe:

3.84oz CO

3.84oz PKO

6.4oz Olive Oil

6.4 Palm Oil

1.56oz RBO

0.56oz Neem Oil

1.28oz Castor Oil

1.28oz Mango Butter

9.728oz H20

3.657oz Lye

(I had originally planned for 10% of neem in the recipe, but after pouring a few drops I realized it had to be much lower... so I made up the 10% with neem and RBO, so that's why the numbers look so funny)!

My temps for combining in both recipes was right at 100 degrees. Could this have been too warm? Maybe with the ambient temp being around 70, it just cooled weird?

Thanks for ANY help! I'm not familiar with the stearic in the palm, but both batches do look a little streaked.

-

Hey everyone!

I'm here with a concern that I can't find when searching the threads. I made two of my first batches of CP soap recently after feeling confident enough of my basic knowledge.

My first batch I borrowed from Susan Miller Cavitch in her Natural Soap Book; it's the recipe titled Soap Essentials I believe... of course, scaled down to fit a two pound batch. The recipe I followed is:

50% Olive Oil

31.25% Coconut Oil

18.75 % Palm Oil

I scented it with .5oz/ppo Patchouli. (Here I assumed my batch would discolor to a light brown due to this EO). I followed through with a stick blender off and on until trace and poured into my silicone mold from WSP (until my wooden ones arrive). I placed this mold with a piece of heavy cardboard on top into a warm 170 degree oven that I turned off immediately. Two hours later I noticed partial gel. Several hours later I got full gel.

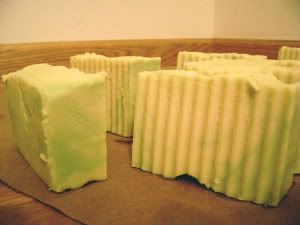

From the photos you can see how creamy it was going into the mold at first, yet it never went back to being creamy after the full gel. Cut, the bars are grainy, beige, and are slightly more translucent.

The second batch was attempted with a completely different recipe, one to lower the oleic oils. I added seven oils in fact. Once again, it went into the mold creamy like pudding, yet it came out looking the exact same way as the first.

And i scented it with NG Lemongrass. This stuff smells like someone getting a perm at the salon! OMG!

Any insight? Is it my mold? Should I not let it gel? I'm in ND so I'm afraid that the temperature around may be too cool, therefore, I thought the oven would be a great place to insulate.

Here are the photos. The first is my first batch. The second is both of my batches cut and looking funny. I really thought they would be whiter and smoother.

-

TOMH,

Thank you for your explanation. I guess CP is sort of like cooking vegetables; raw is best to get the most nutrients, and it's a mystery when the oils have been "cooked".

-

Thanks, JacquiO! I am doing CP (I forgot to mention) method.

I really appreciate your input. My main concern is simply having the essence of neem saponify and not be as "potent" in the final product. I'm not actually really sure how much of it is lost during saponification.

-

Is it advisable, in order to retain as much of an oil's essential properties, to add oils AFTER mixing the lye water with the base oils? In other words, if I am looking to use neem oil in my recipe to reap its possible skin healing benefits, should I wait a few second/minutes until the lye solution is mixed in with my olive, coconut, etc. oils to pour in the neem?

Or does it even matter?

-

I also just tried this wax (among the others I sampled) and am not getting the soot problem either! It does have a good scent throw with the one scent I have tried so far. I've been successful with CD wicks as well as Zinc. Now time to pick one!

-

SSolis, I can't thank you enough for your posting. I am in need of some and was scared to fork out the money on it if it was going to let me down again. Thank you so much! Portia

No problem, Portia! I was going to do it eventually anyway. I really wanted to believe! I really wanted my Joy Wax back!

-

How many pounds per case? What is the formula of this wax (paraffin/soy) ?

Thanks

I thought I remember from way back when I started using this wax that NG had mentioned a 98% soy ratio. However, those numbers aren't on the site any longer. The ratio may have changed or they didn't really know to begin with?? On their skid-load info., they state each case is 54-60 pounds.

-

Results are in! Joy Wax is rockin'! It' just as I remember when I first began using it. No frosting, excellent adhesion, no cracking, great HT and CT! Just as creamy out of bag as ever. I did only order one slab, so let's cross our fingers that the case will prove just as perfect! Here are some pics after candle cooled and also after 5 hour power burn.

Also, I tried to be as clumsy with the candle pouring process as possible, not really paying too close attention to pouring at the exact temp, pouring fast not slow, and not heating jars. I also have air set at 71 here so they cooled in a colder environment.

My wicking from the old Joy is the same as I tested with; no need to wick up!!

-

I'll be sure to post thoughts and impressions. I didn't really care for the WOW wax, but I have never worked with paraffin before either. My blended 50/50 of the WOW and Ecosoya CBA is absolutely my haven if Joy poses issues.

pdevine, did you have any other issues with the Joy besides it just cracking? I can't really remember if my wicking was changed before I stopped using it.

-

Not sure if I should be holding my head in shame or my hands up in excitement, but I ordered a slab of Joy wax today! I guess the testing will determine how I react to this wax I so loved before!

Being in wax limbo has it's pros and cons...

-

Cool Crush

Chill Chomp

Chill Chap (LOL! or The Chap's Chill)

What's with me and double Cs?

-

I've actually thought about diving back into Joy Wax, too. I had to close up shop for almost two years (didn't want to mess with candles, shipping and the heat of Arizona) but now that we are in North Dakota I have a different problem... it being too cold!

I have a moderate crackling (which differs from cracking if you will) of the wax in containers going on here and I cannot fix it with any different pour temperature or thermal cooling. I may try my luck with Joy again, but who knows! So many decisions! I think Joy may help with my crackling issues.

sandi

-

Awesome! Thank you for the response. I'll keep truckin' with it and see what comes of it! Right away I began blending it with my soy so I'm not sure which way I will eventually go!

-

I have tested it. It's a good wax, really good throw cold & hot and pretty easy to wick.

So I am testing the Wow in an 8oz square Mason with 6% FO load. I have a CD 8 popped in there now, but the flame still seems rather large and I notice a tad bit of soot when a draft occurs. What wicks would you suggest?

Suggestions please

in General Soap Making

Posted

O! I misread, thinking that she ... well, yeah! She can totally get a good white and a black soap is sold at Natures Garden!

http://www.naturesgardencandles.com/candlemaking-soap-supplies/item/blacksoap/melt-and-pour-soap--BLACK-Colored-Melt-and-Pour-Soap--2-lbs..html

(I was thinking you were going cold process and were only familiar with M&P)